The EBM Opportunity

Overview

Enhanced biological mineralization (EBM) in high-grade tailings processing refers to the use of biological processes to recover valuable materials and minimize environmental impact from mine waste with high concentrations of residual minerals

The EBM Project is a substantial, high-grade tailings project which has amassed reserves over the past 70 years from four distinct mining operations. It includes a fully operational, well-maintained multi-processing plant that is ready for immediate use.

The plant recently concluded a successful 2.5-year rental contract with Glencore, one of the world’s largest mining companies, during which it processed substantial volumes of cobalt and uranium ores. Since the conclusion of Glencore’s ore processing activities, the plant has been routinely tested and started up each month to ensure continuous operational readiness. Additionally, EBM invested $11 million in a comprehensive refurbishment, upgrading tanks, liners, and piping, as well as installing two large vacuum filter presses, further enhancing the facility’s efficiency and capabilities.

Joint Venture

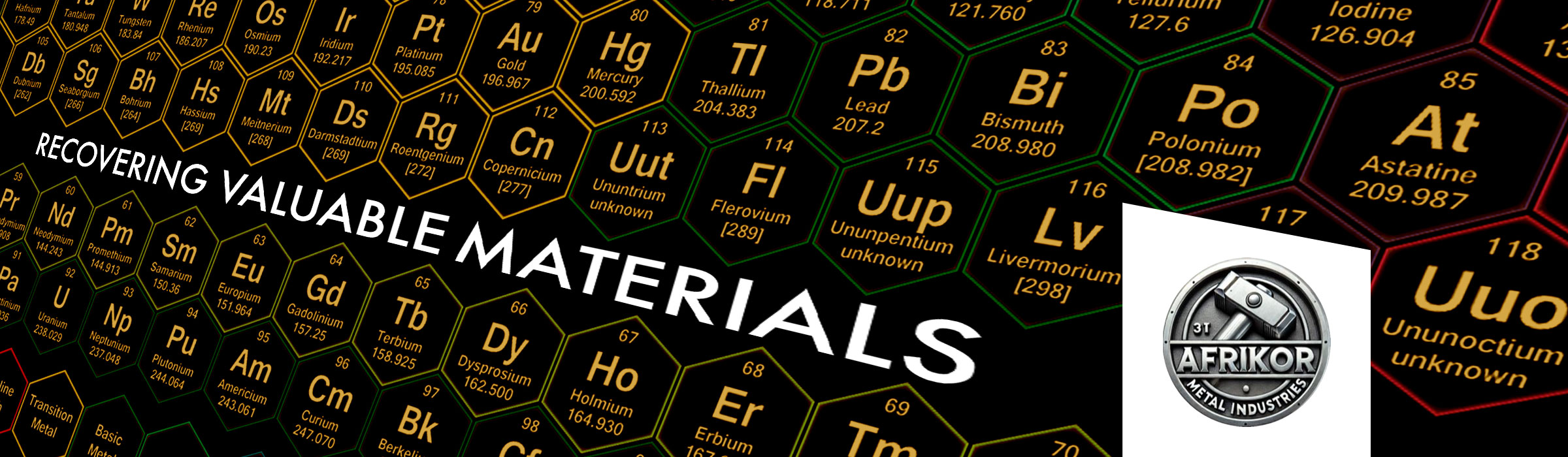

Afrikor Metal Industries (PTY) LTD, in a 51% joint venture with Golkor, has finalized the acquisition agreement of the EBM Facility located in Springs, Gauteng, South Africa. The project went to tender and was won by AMI for the sum of $10 million. The facility is focused on the reclamation and re-processing of economically valuable minerals from historic surface deposits—specifically zinc, lead, silver, iron, and gold—while also addressing environmental rehabilitation. The project, referred to as the “EBM Project,” integrates resource recovery with environmental stewardship, aligning with modern ESG mandates.

Location Advantage

Strategic Positioning: Situated 45 km east of Johannesburg, South Africa’s commercial hub.

Infrastructure-Ready: Connected by a major 4-lane federal highway and proximate to existing rail lines, the site has easy logistics for incoming feed material and outgoing refined product.

Existing Footprint: The 240-hectare site (Farm Daggafontein 125IR) has ample space for expansion and diversification into other industrial applications.

Ideally located in a mining district with over 30 large historical dumps within 10km radius, that all have value.

Industrial Area with approved tailings storage facilities

FACILITY STATS

Processing Plant Overview

Scale

The plant, spanning 20 hectares, is considered world-class in scale and functionality, having served Anglo Gold, Zincor, Exxaro, and Glencore, each of which enhanced its infrastructure and equipment. Designed to handle multiple ore streams simultaneously, it operates like four processing plants in one, with permits to process gold, silver, lead, zinc, copper, cobalt, and uranium. Equipped with advanced machinery and extensive storage—including acid facilities and 10,000 square meters of dry storage—the plant’s replacement value exceeds $200 million, though total investment over time has likely surpassed $500 million. It operates with a substantial 45 MW power capacity.

- Full maintenance team on site (31 persons) run the plant for 2 days per month to keep everything live

- This plant can be fully on line within 3 months of startup.

- Second line can be fully operational within 7-8 months

Capabilities

- Multi-commodity handling: gold, silver, lead, zinc, copper, cobalt, and uranium.

- Acid and dry storage: 10,000 m² of dry storage space; refurbished acid storage tanks.

- Power: 45 MW dedicated power via Eskom, distributed through a robust substation network.

- Water: Borehole-fed water system with a Water Use Licence allowing for 660,000m³/year, pending approval for expansion to 960,000m³/year.

- Effluent Treatment: On-site ETP can treat up to 2 million liters per day.

- Refurbishment Investment: Over $10.6m USD invested to date for tank, piping, filter press upgrades, and operational readiness.

- Historical Use: Previously leased to Glencore for 2.5 years (until Oct 2023) for cobalt and uranium ore processing—operated successfully and profitably.

Mine Life

- Plan to treat Dumps 1 & 2 for 8.2 years mine life

- Followed by 5 years of Dump 3

- Dams 3 Iron- Zn has projected 6 years mine life

- Mine life 13.2 years of existing mine life

- Greater than 20 years of mine life with existing tailings.

- Can buy in multiple nearby dumps rich in metals & Uranium (Plant is permitted to treat Uranium.

- Can generate over $100m in profits from the licensed High Hazard Dam which can hold 2Mt of any type of waste.

Plant covers 20 Ha site and is essentially 4 plants in one.

Reserves

- Two of four dams to be treated contain

- 2.3Mt @ 8% Zinc (equivalent to 3 g/t Au)

- 0.7Mt @ 8% Pb, 5% Zn;170 g/t Silver equivalent to 6 g/t Au

- $611M of recoverable metal value with projections of $356M in EBITA.

- Pilot test work on all reserves have been down at scale so ready to implement.

- Conventional technology will extract the ore. It has been piloted and tested on large scale.

Permits

- Fully Permitted to start production

- Tailings, Water Usage, Water disposal, Air, Transport, Acid treatment facility permit, filtration permits etc.

Labor

- All necessary senior staff on Care & Maintenance work.

- Operators contacted ready to return.

- Full workforce back within 3-4 weeks.

- A high standard of safety and security was observed at the mine site. It has a well-designed system that meets all the country regulations.

Tailings & Mineral Resource Potential

Tailings Dump & Residue

The 7L3 tailings and residue dump is situated south of the processing plant area.

The base of the dump is made up of gold and silver containing tailings from pre-1966 gold mining operations on site, referred to herein as the main 7L3 Gold Tailings Dump.

The dump has since been used as a base metal residue disposal site. The upper part consists of zinc and iron-rich residues, namely the Neutral Leach (zinc-rich) and Iron-Zinc residue dams. These have been placed in different areas on top of the main 7L3 Gold Tailings Dump.

There is also a paddock next to the Neutral Leach Residue Dam where the Lead-Silver Residue was previously deposited. This residue has since been moved to the H:H waste disposal and storage facility.

The main 7L3 Gold Tailings Dump was approximately 10-12m high before the residues were deposited on top. The current height of the dump is up to 25m in some areas.

Resource Estimate

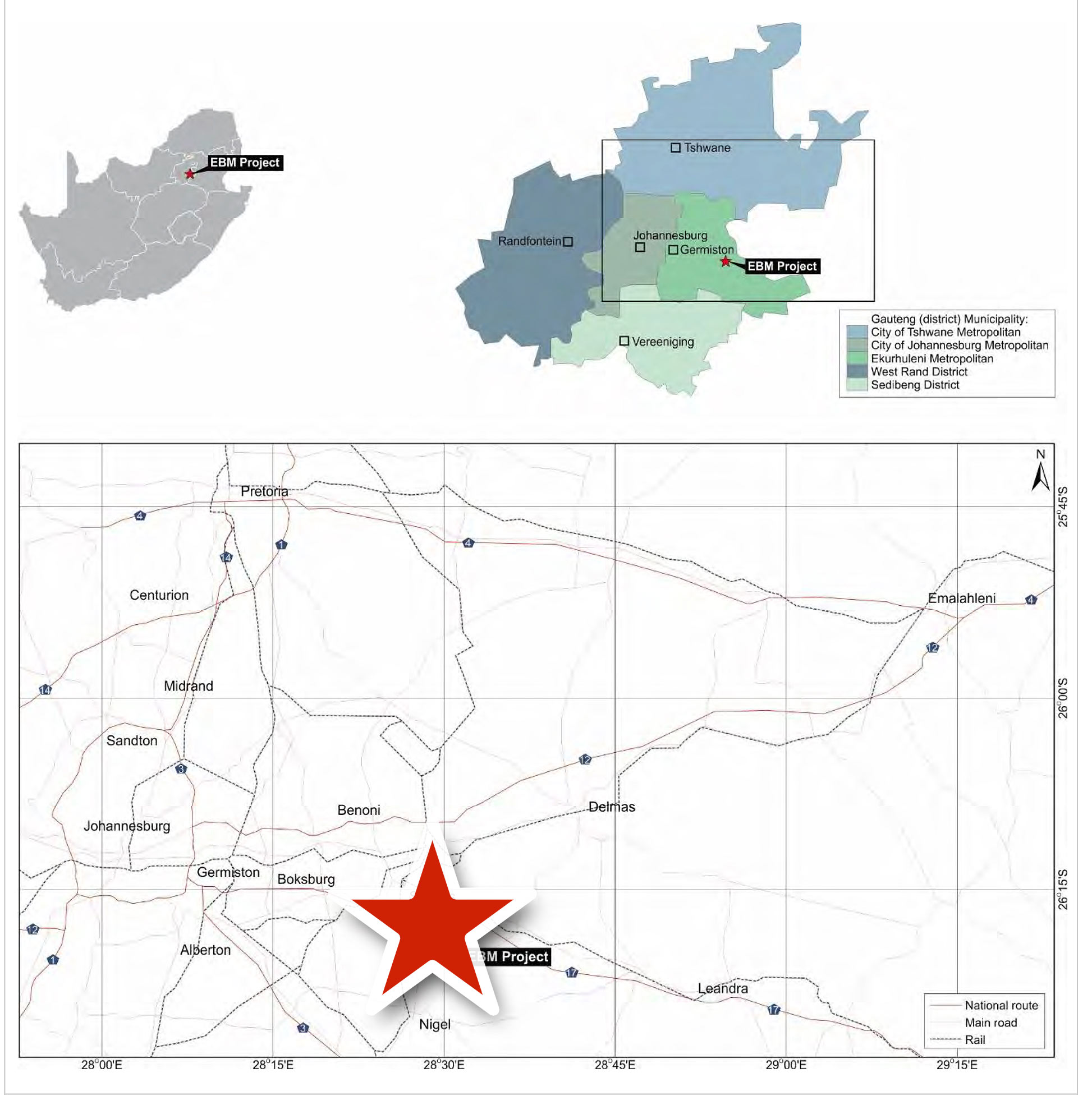

Dam Locations:

(1) Neutral Leach Dam – 3Mt @ 8% Zn

(2) HH Dam – 0.6Mt @ 8% Pb, 5% Zn, 170 g/t Ag

(3) Iron Residue Dam – 1.3Mt @ 9% Zn, 5% Pb

(4) Gold Dam – 9Mt @ 0.78 g/t Au & 46 g/t Ag

(5) Zinc Acid Leach & Cementation Plant

(6) Zn, Pb, Ag, Cu Leach & Cementation Plant

Note scale of Dumps and proximity to plant

Utilities & Infrastructure

There is appropriate infrastructure and sufficient space to carry out the processing operations on site. Some of the historical plant infrastructure and buildings that no longer serve a purpose have been / are being demolished, and the associated footprint areas largely rehabilitated. Useable parts are being refurbished, and new equipment commissioned where required. A plan view of infrastructure available on site is presented below.

H:H Waste Disposal and Storage Facility

The certified H:H waste disposal and storage facility is a valuable asset. There are only a few such hazardous waste sites in South Africa, with a number of them coming to the end of their lives. The EBM facility is one of the few partially used hazardous landfill sites, which will retain its full capacity post the re-processing of the Lead-Silver Residue currently deposited in it. The current rate for disposing of hazardous wastes is approximately $207.46/t. With the facility’s current capacity of approximately 2Mt, this equates to a potential ZAR8bn revenue. There is minimal management cost associated with the landfill site, and the necessary infrastructure for the management of the facility already exists. This facility has been included in the Bidder’s Financial Model and assumes that, on average, 663kt of hazardous waste will be deposited in the facility annually for over 15 years. Only a 1Mt capacity has been modelled, which equates to $207 million USD. EBM also has an opportunity to outsource this facility to a specialist environmental company and charge a royalty on the disposal charge.

Power Supply

Power requirements for the reclamation and processing operations can be met from the current system whereby EBM has an electricity allocation agreement with Eskom. EBM’s electricity supply is therefore from the main sub-station (6,600V distribution) which is connected to the Eskom no.4 transformer. This main sub-station distributes electricity to a total of five other sub-stations servicing the site. Power supply to the site has not been interrupted even during the period in which South Africa experienced rotational “load shedding”.

- 6,600V distribution from Eskom via a dedicated substation.

- Uninterrupted supply even during national load-shedding.

Water Supply

Potable water from the municipality will be limited to ablution and kitchen facilities. Water requirements for the processing operations will be sourced from existing boreholes on site as far as possible. In addition, borehole water will be supplemented with supply from Rand Water when the requirement for clean water in production arises. Under the relevant Water Use Licence (“WUL”), EBM is permitted to extract a maximum volume of 660,000m3 per annum for use in the processing operations, and also as a means of decontamination. The contaminated water is treated through the existing ETP on site (see Figure 15). The ETP can treat volumes of up to 2Ml (million litres) per day. EBM has submitted a WUL amendment application to increase the extraction volume from 660,000m3 per annum to 960,000m3 per annum.

- Potable water sourced from the municipality (for domestic use).

- Boreholes supply the bulk of process water, supplemented by Rand Water if needed.

- Roads & Transport: Fully maintained internal bitumen roads support heavy haulage and processing logistics.

Laboratory Facilities

The in-house analytical laboratory is functional and fully equipped with instruments for analysis of base metals, precious metals and mineralogy. The laboratory also houses SANAS accredited balance equipment, and implements an accredited quality control system to ensure continuous monitoring of process conditions and product quality.

- Fully operational, SANAS-aligned analytical laboratory.

- Capable of testing base and precious metals and conducting mineralogical studies.

- Revenue Opportunity: Potential lease to third parties or contract analysis services.

- 2 x ICP Lab Automated Analysis machines

- 3 x AAS machines

- 1 x XRF Machine

- 2 x Colorimetric machines

Roads

Roads within the property are in good condition, enabling free movement of trucks and vehicles throughout the area.

Other Site Infrastructure

Ventilated and air-conditioned offices; refurbished acid storage tanks, equipped with new inners; diesel storage facility; two weighbridges; stores containing current stock of chemicals and essential parts and pumps for the plant; and heating systems such as heavy fuel and oil boilers.

Highlighted Plant Sections

New Leach plant: Cementation and precipitation + large vacuum filters

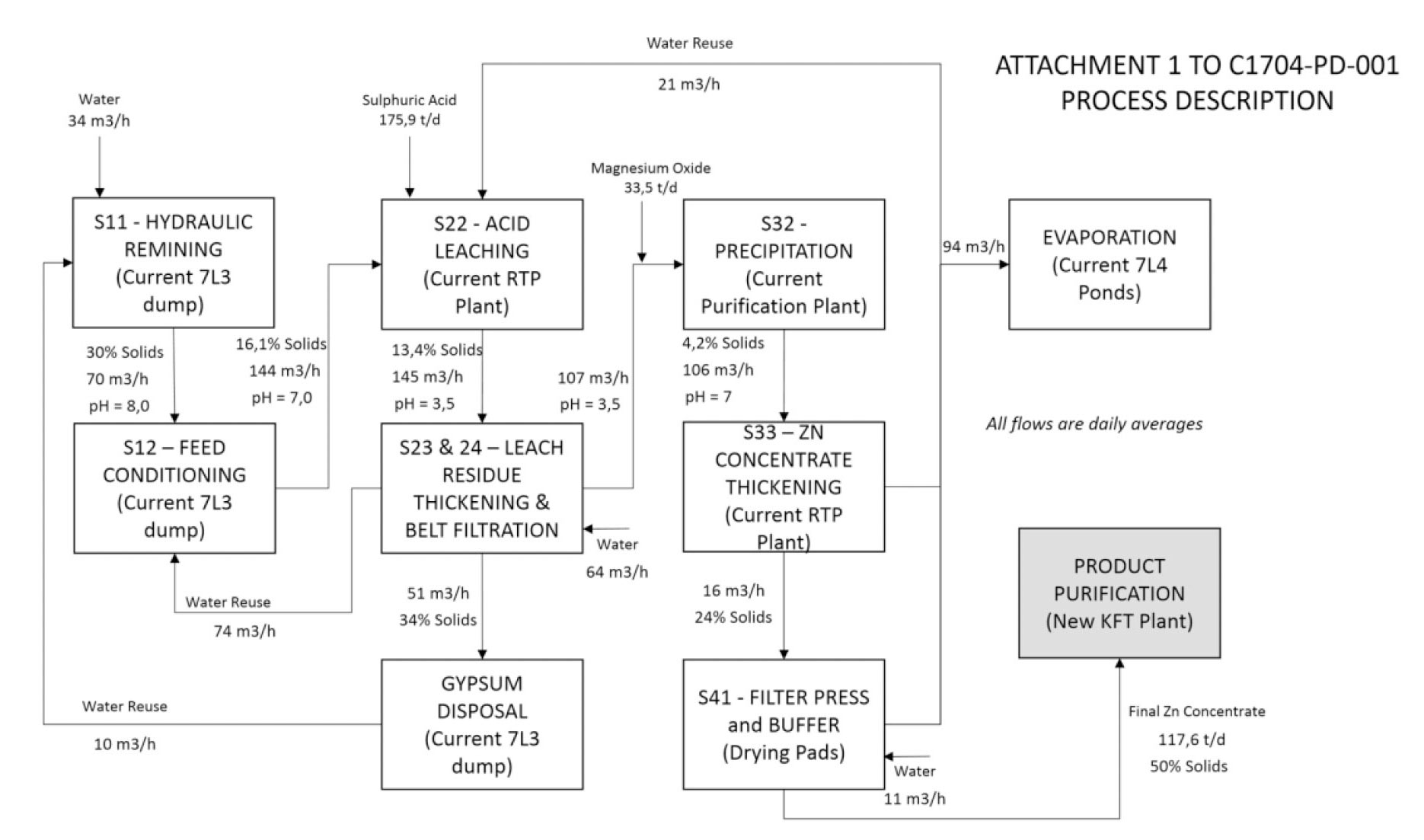

Flow Sheet for Leach Cementation Process

Large storage facilities purpose-built for acids etc.

General view of plant from Tailings Dam side.

Expansion & Future Opportunities

Zinc First Approach: Zinc re-processing will be the initial phase, followed by recovery of lead, silver, iron, and gold.

Gypsum By-product

- A significant volume of gypsum will be produced during reprocessing.

- Can be sold as-is (“dirty gypsum”) or further beneficiated into higher-value product.

Third-Party Processing Hub

- The site’s power, permitting, and infrastructure position it as a long-term toll treatment hub for regional feedstock.

Uranium License Potential

- EBM can apply for a uranium processing permit.

- This opens doors for processing third-party concentrates and further revenue streams.

News & Press

Scientists extract silver from e-waste using cooking oil (Fox News)

Scientists extract silver from e-waste using cooking oil (Fox News) SilverSeek Thu, 09/18/2025 - 04:02 [...]

India’s silver imports to gain momentum from strong investment demand (Reuters)

India's silver imports to gain momentum from strong investment demand (Reuters) SilverSeek Wed, 09/17/2025 - 11:58 [...]